Press release -

The new HVAC air filter CamCarb XG, a game changer in molecular contamination control innovation

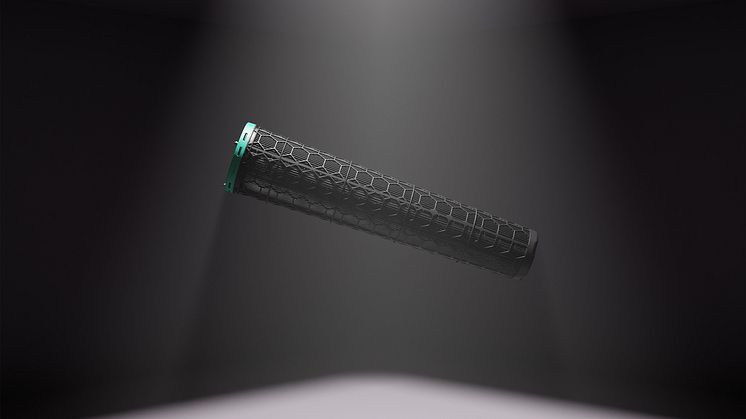

Stockholm, 28 August 2023 – Camfil announces the launch of the latest innovation in molecular filtration products with the CamCarb XG. Companies targeting gas-phase contaminants in various applications such as odour, pollution or corrosion control will gain superior-in-class results with performance and protection.

Molecular contamination control (MCC) products capture molecules, gases, and vapors from the air. Those contaminants cannot be trapped by traditional particle filters. Molecular filters are also known as gas-phase filters, chemical air filters or activated carbon filters in different countries and applications.

The Camfil investment into research and development has led to the optimisation of the shape of the traditional cylinders ultimately resulting in minimised pressure drop and maximised media utilisation. Research and development on this have been at Camfil’s multiple laboratories and ISO 10121 test facilities around the world and have been focused on fluid dynamics and media adsorption.

“The CamCarb XG boasts a unique combination of high removal efficiency, low resistance to airflow and long lifetime, resulting in a very low “Total Cost of Ownership” (TCO) for our clients,” says Dr Guillaume Gallet, President of Camfil molecular contamination control business division.

“In addition, thanks to its ergonomic design, the time necessary for filter installation and replacement results in up to a 50% reduction versus conventional products, making it a very attractive solution for services and facility management companies. It’s brand-new conical design reduces energy consumption up to 35% and assists end-users to cut down on their CO2 footprint and energy bills. This product is a game changer and far ahead of anything currently available on the air filtration market. The product will be first available in Asia Pacific, followed by Europe, Middle East, Africa (EMEA) and North America in the last quarter of 2023.”

The adsorptive media used in CamCarb XG can be anything from activated carbon or activated alumina materials and has been developed and tested in Camfil laboratories. “Our molecular contamination control business division commits to sustainability. This is evident in every step of the life cycle of the product. Camfil’s approach to problem-solving, innovative design, precise process control, and customer focus all contribute to product development that aims to conserve more, use less, and find better ways to protect people, processes, and the environment.” Elaine Seet, Regional Product manager, Camfil Industrial Molecular filtration.

For more information on the CamCarb XG or for local representative contact details, visit the CamCarb XG page here - CamCarb XG | Camfil

Related links

Topics

Categories

The Camfil Group is headquartered in Stockholm, Sweden, and has 31 manufacturing sites, six R&D centres, local sales offices in 35 countries, and 5600 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil can help you to protect people, processes and the environment, visit us at www.camfil.com.