Press release -

Gas Turbines Breathe New Life

Alto Garda (AG) Power in Italy manages a cogeneration power plant with high availability requirements (7900 hours/year) where they supply electricity and steam to paper mills. Additional requirements include supplying district heating for the town of Riva del Garda, including offices, schools, kindergartens, etc.

In an effort to increase the performance of the 44 MW gas turbines, Camfil Power Systems was asked to optimize their existing filtration system. The aim of the collaboration was to decrease the total filtration system pressure drop (dP) to achieve the following:

- More power output for the same fuel consumption,

- Extended filter lifetime, as well as less time and effort required for filter replacement,

- Higher engine protection and availability.

THE SITE

The sites are located in coastal to land based conditions, where air quality can be challenging. Relative humidity is moderate to high with an average of 73%, as well as significant precipitation and fog/mist.

ORIGINAL FILTER CONFIGURATION

The original installation has a 2-stage system design consisting of pleated pre-filters with G4 efficiency, and final filters with F9 efficiency.

This system presents the following drawbacks:

- High dP spikes, especially in high humidity, rain, or fog conditions result in:

- Pre-filter replacement every 4 months,

- Final filter replacement every year.

- Low filtration efficiency and no drainage capabilities cause engine degradation.

- Rigid design limits the choice of products for replacement.

CAMFIL SOLUTION

Camfil conducted several site surveys to recommend the optimal air filter solution to enhance the performance of the engines. The shortest possible installation time during scheduled maintenance was a fundamental prerequisite.

Based on environmental and operational conditions, the OEM and AG Power decided to upgrade the existing system to a 2-stage static filter solution. The system consists of two air tight filter banks holding the Cam-Flo GT Hybrid F7 pocket air filters and the CamGT 3V-600 E10 final EPA air filters.

This system has the following advantages:

- Low and stable dP, even under wet and humid conditions:

- pre-filter life time expectation > 1 year

- final filter EPA class lifetime expectation > 3 years,

- Greater engine protection due to EPA efficiency and efficient water drainage,

- Flexible design.

PERFORMANCE

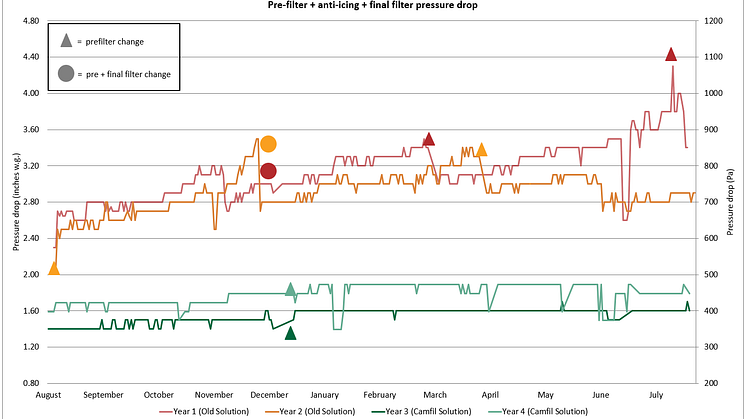

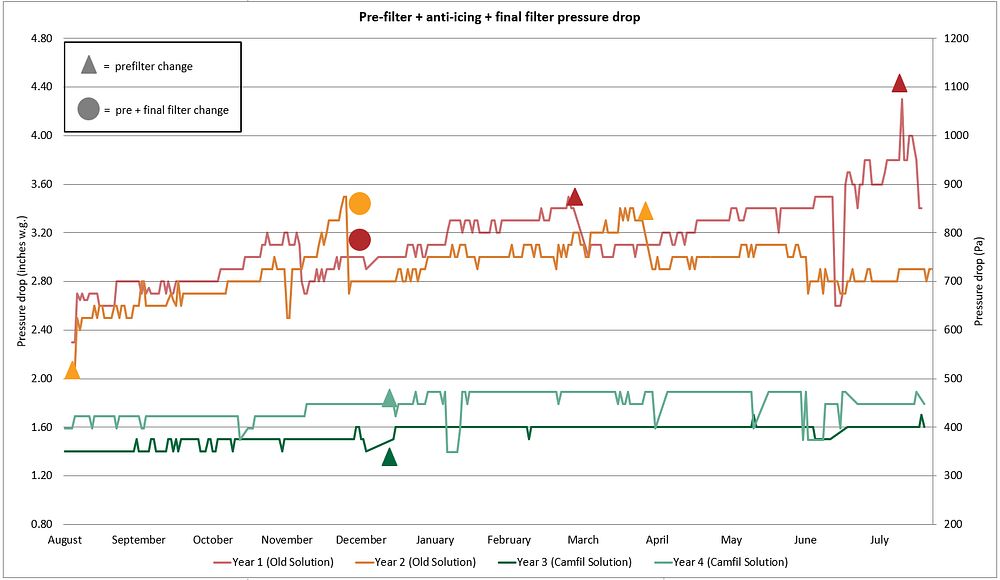

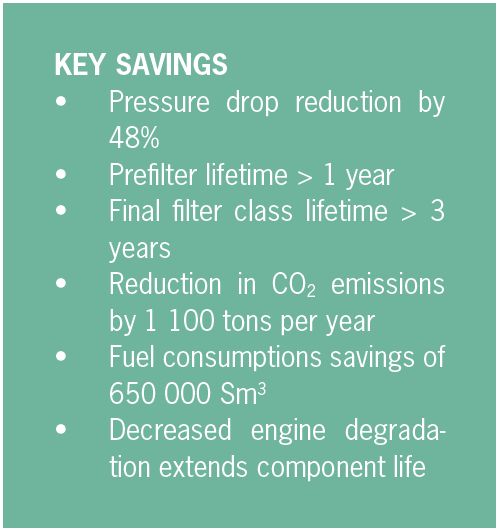

The graph below compares typical pressure drop performance of the previous installation and the Camfil gas turbine filtration solution. Before the upgrade, pressure drop averaged 750 Pa (3"), and multiple shutdowns for pre-filter replacement were required throughout the year.

The Camfil solution, two years later, continues to maintain a low and stable pressure drop at an average of 375 Pa (1.5" w.g.). As a result, pre-filter replacement decreased to once per year during the plant's annual outage, without a final filter change yet.

SAVINGS

Due to pressure drop savings, as well as fouling reduction from the higher efficiency solution, AG Power will have saved approximately 650 000 Sm3 on fuel consumption.

Additionally, they were able to reduce their CO2 emissions by approximately 1100 tons per year.

Calculate your carbon savings using Camfil's free online calculator by visiting www.BoostToReduce.com.

About Camfil Power Systems:

Camfil Power Systems specializes in air inlet and acoustical systems for turbomachinery, including gas turbines, generators, industrial air compressors, and diesel engines.

Our engineering experts continuously strive to protect this high-value equipment by designing the best filtration and acoustical solutions to meet the priorities and requirements of original equipment manufacturers (OEMs), engineering procurement construction companies (EPCs), operators, and end users. They can be assured that their equipment will operate in the most profitable way, with maximum availability and reliability.

Camfil Power Systems is part of the Camfil Group, a world leader in the development and production of air filters and clean air solutions, with 30 manufacturing sites, six R&D centers, and local sales offices in 30 countries. For information or to contact a Camfil Power Systems representative, visit www.Camfil.com or use the Contact Locator.

Related links

Topics

Categories

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control, and a strong customer focus we aim to conserve more, use less, and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 33 manufacturing sites, six R&D centres, local sales offices in 30 countries, and 4,800 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil can help you to protect people, processes, and the environment, visit us at www.camfil.com.